Understanding the Art of Welding: How to Stay Clear Of Undercut Welding Issues for Flawless Fabrication Results

By understanding the root causes of undercut welding and executing efficient methods to avoid it, welders can raise their craft to new levels of excellence. In the pursuit of flawless fabrication results, mastering the art of welding to avoid undercut issues is not just an ability yet a need for those making every effort for excellence in their work.

Understanding Undercut Welding

To stop undercut welding, welders must make sure appropriate welding specifications, such as readjusting the present, voltage, traveling speed, and preserving the appropriate electrode angle. By understanding the causes of undercut welding and implementing preventive measures, welders can attain high-grade, structurally audio welds.

Reasons of Undercut in Welding

Understanding the aspects that add to undercut in welding is necessary for welders to produce top notch, structurally audio welds. Inadequate welding present or wrong welding speed can additionally add to undercut. Comprehending these reasons and applying correct welding techniques can assist stop damaging concerns, ensuring strong and long lasting welds.

Techniques to Avoid Undercutting

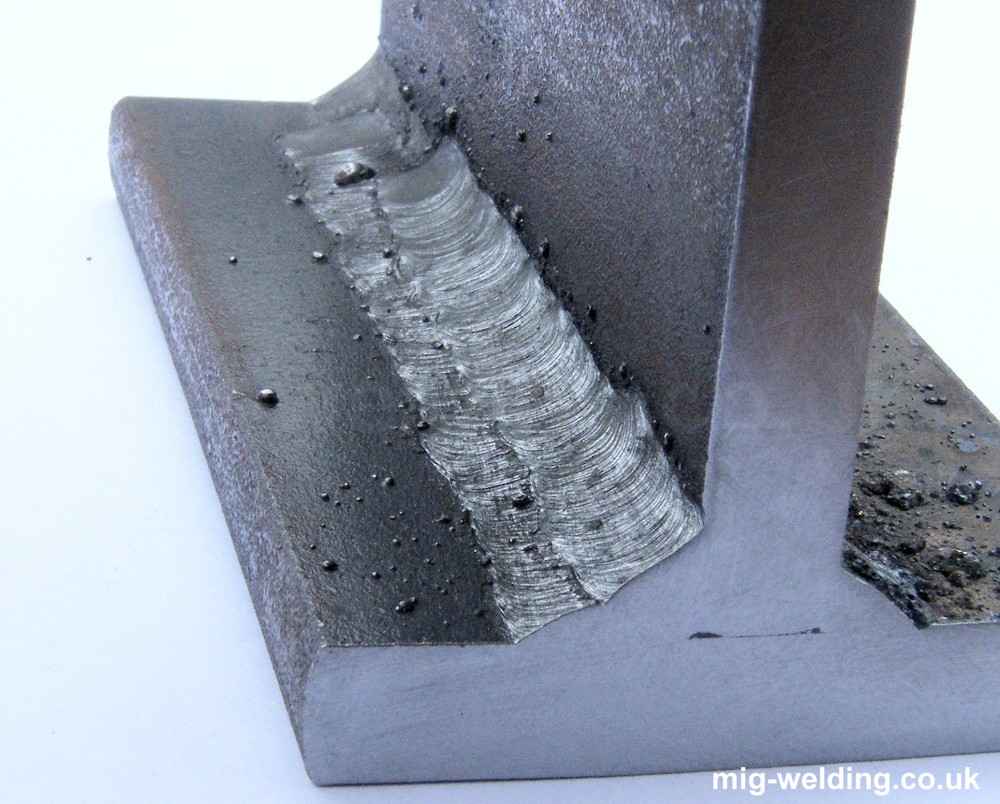

To minimize the threat of undercutting in welding, welders can employ tactical welding techniques focused on enhancing the quality and integrity of the weld joints. One effective method is to adjust the welding parameters, such as voltage, current, and travel speed, to ensure proper heat input and deposition. Maintaining a suitable electrode angle and guaranteeing consistent travel speed can also aid protect against undercut. In addition, making use of the proper welding strategy for the certain joint setup, such as weave or stringer beads, can add to reducing damaging. Preventing weld undercut.

Employing back-step welding methods and regulating the weld bead profile can additionally aid distribute warm uniformly and decrease the risk of undercut. Routine examination of the weld joint during and after welding, as well as carrying out top quality assurance steps, can assist in addressing and spotting damaging concerns helpful resources without delay.

Significance of Appropriate Welding Specifications

Picking and keeping appropriate welding parameters is necessary for attaining effective welds with marginal defects. Welding parameters refer to variables such as voltage, current, travel speed, electrode angle, and protecting gas flow rate that directly affect the welding process. These specifications need to be meticulously readjusted based upon the kind of product being bonded, its density, and the welding method used.

Proper welding criteria make certain the right amount of heat is put on thaw the base steels and filler product consistently. If the specifications are set as well high, it can result in excessive heat input, causing burn-through, spatter, or distortion. On the other hand, if the parameters are too reduced, insufficient his comment is here combination, lack of infiltration, or damaging may occur.

Quality Control in Welding Workflow

Conclusion

To conclude, grasping the art of welding requires a detailed understanding of undercut welding, its reasons, and methods to avoid it. By guaranteeing correct welding specifications and implementing top quality assurance techniques, perfect manufacture results can be attained. It is necessary for welders to consistently make every effort for excellence in their welding procedures to avoid undercut problems and produce top notch welds.

Undercut welding, a common flaw in welding processes, happens when the weld steel doesn't appropriately fill the groove and leaves a groove or anxiety along the bonded joint.To avoid undercut welding, welders must ensure appropriate welding criteria, such as adjusting the present, voltage, traveling speed, and preserving the right electrode angle. Poor welding wrong or current welding speed can likewise add to undercut.To reduce the danger of damaging in welding, welders can employ tactical welding methods intended at boosting the quality and integrity of the weld joints.In final thought, grasping the art of welding calls for a complete understanding of undercut welding, its reasons, and methods to prevent it.